CEMEA SAS primarily focuses on research and development in the field of materials science, with a specific emphasis on surfaces and interfaces modification of advanced materials, including those used in biomedical applications. The investigation performed by CEMEA SAS in this area has yielded impressive results.

A team of authors from CEMEA SAS, Assoc. Prof. Mgr. Anna Kityk, PhD, and Assoc. Prof. Ing. Miroslav Hnatko, PhD, have played a key role in developing a new technology for electrochemical surface modification of biomedical titanium and titanium alloys. This innovative approach utilizes environmentally friendly electrolytes based on deep eutectic solvents.

Collaborating with the Biomedical Engineering Company (Kosice, Slovak Republic), a leading producer of 3D-printed titanium prostheses and implants, CEMEA SAS has been able to formulate ambitious plans and set tangible tasks that align with market demands. Through this research partnership, all goals and plans have been successfully implemented.

Over the years, numerous endeavors have been made to enhance the surface properties and bioactivity of titanium prostheses and implants, aiming to minimize implantation failures and accelerate the healing process. While some advancements have been achieved in surface modification techniques for titanium products, the quest for effective, affordable, rapid, and cost-efficient solutions have remained a pressing challenge. The conventional method of titanium processing, sandblasting, has exhibited notable drawbacks for biomedical applications due to surface contamination caused by abrasive particles. Consequently, manufacturers of prostheses, implants, and researchers were confronted with the need to attain a noncontaminated surface that possesses improved wettability, high corrosion resistance, and substantial biocompatibility.

The emergence of an innovative technology of electrochemical surface treatment has addressed these requirements for titanium and its alloys. This innovative approach utilizes environmentally friendly deep eutectic solvents, effectively eliminating surface contamination while simultaneously enhancing key characteristics. Notably, this technique significantly improves the wettability of the surface, enhances corrosion resistance, and achieves a high level of biocompatibility. With these advancements, the technology fulfills all the desired criteria for surface modification of titanium prostheses and implants, providing a promising solution for reducing failures in implantation practice and expediting the healing process.

Deep eutectic mixtures, the new generation solvents, were selected as electrolytes for the electrochemical treatment of Ti and Ti alloys due to their numerous advantages over aqueous and non-aqueous systems. These solvents belong to a novel class with attractive characteristics, including the ability to biodegradation (100% biodegradation by bacteria and fungi within 28 days in the natural environment). They exhibit high thermal, chemical, and electrochemical stability, possess a neutral pH, and demonstrate low corrosivity, ensuring safety for both humans and the environment. The advantageous combination of physicochemical properties offered by these new electrolytes enables efficient and flexible designing of the surface properties of titanium products. One significant highlight is that the electrochemical treatment in deep eutectic solvents does not require the use of toxic additives or extreme temperatures, which were demanded in previously proposed and patented electrolytes for titanium anodization. The availability and relative low price of the electrolyte components, coupled with the efficiency and ease of processing, position this new technology as a promising alternative to the most-common methods of Ti and Ti alloy processing.

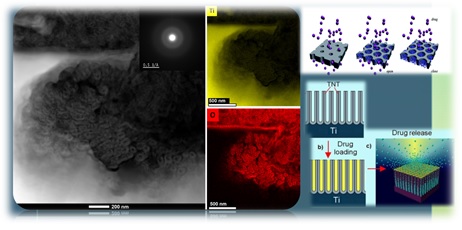

Particular emphasis should be placed on the remarkable potential for micro- and nanoengineering of titanium-based surfaces using the proposed technology. Deep eutectic solvents offer the possibility of developing micropores, nanopores, and nanotubes, opening up new ways for drug delivery, surface modification with biomolecules, and hydroxyapatite integration. This advancement in micro and nano leveling has the potential to elevate these processes to a new level. Notably, the creation of a combined hierarchical micro and nano structure, mimicking the intricate nature of real bone tissue, on the surface of prostheses and implants can significantly enhance cell attachment and growth, ultimately improving biocompatibility.

Obvious progress and achievements in the implementation of the project and the solution of existing research tasks were noted by the industrial partner. Besides, the results obtained became the basis of two European and one International patent applications.

- European patent application entitled “Method for electrochemical surface treatment of biomedical products made of titanium or Ti-based alloys” was registered under the number 22193733.7 (2.09.2022).

- European patent application entitled “A method for electrochemical surface treatment of biomedical products made of titanium or Ti-based alloys” was registered under the number 22204696.3 (31.10.2022).

- International patent application entitled “A method for electrochemical surface treatment of biomedical products made of titanium or Ti-based alloys” was registered under the number PCT/SK2023/050006 (12.04.2023).

The presentation of the results at the international forum organized by Taiwan showed a significant interest in the achieved outcomes. The new technology has also attracted the interest of local manufacturers. As a result of a joint meeting and negotiations, a cooperation agreement was signed with the company MIKROCHEM GROUP (Slovak Republic), which is manufacturer and R&D of new active pharmaceutical ingredients of new medicine and treatments, that can save lives and have a positive impact in the society.

Technology Transfer Office SAS nominated innovation of

A. Kityk and M. Hnatko and their team for the “Technology Transfer Award in Slovakia 2023” competition, in 2 categories: “innovation” and “innovators”.

Some additional information can be found on the web pages of Technology Transfer Office SAS: